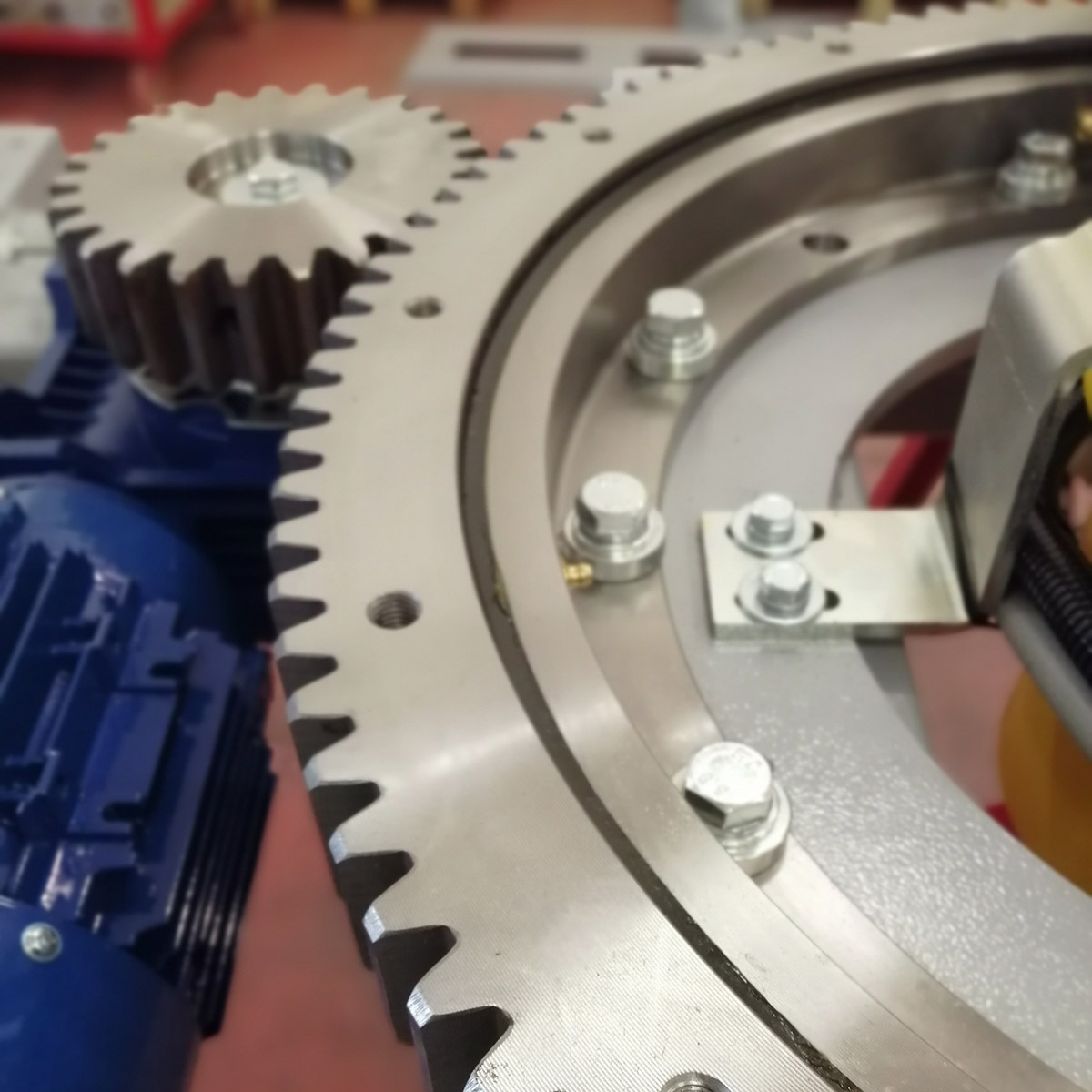

ROTATION RING BEARING

Precision ring bearing for high load capacity, low coefficient of friction and long service life.

MOTORIZED PRESSING PLATE (option)

The motorized pressing plate controlled by inverter allows to stabilize any pallet.

CLAMP, BLOW, CUTTING AND WELDING

Clamp, blow, cutting and welding are mounted on board of the turntable. The welding is done on contrast to avoid contact with the product.