ROLLERTECH

Stretch film pallet wrapping robot.

High performance Robot. Robust and Reliable.

Self-propelled machine wraps pallets of any size, weight, and shape.

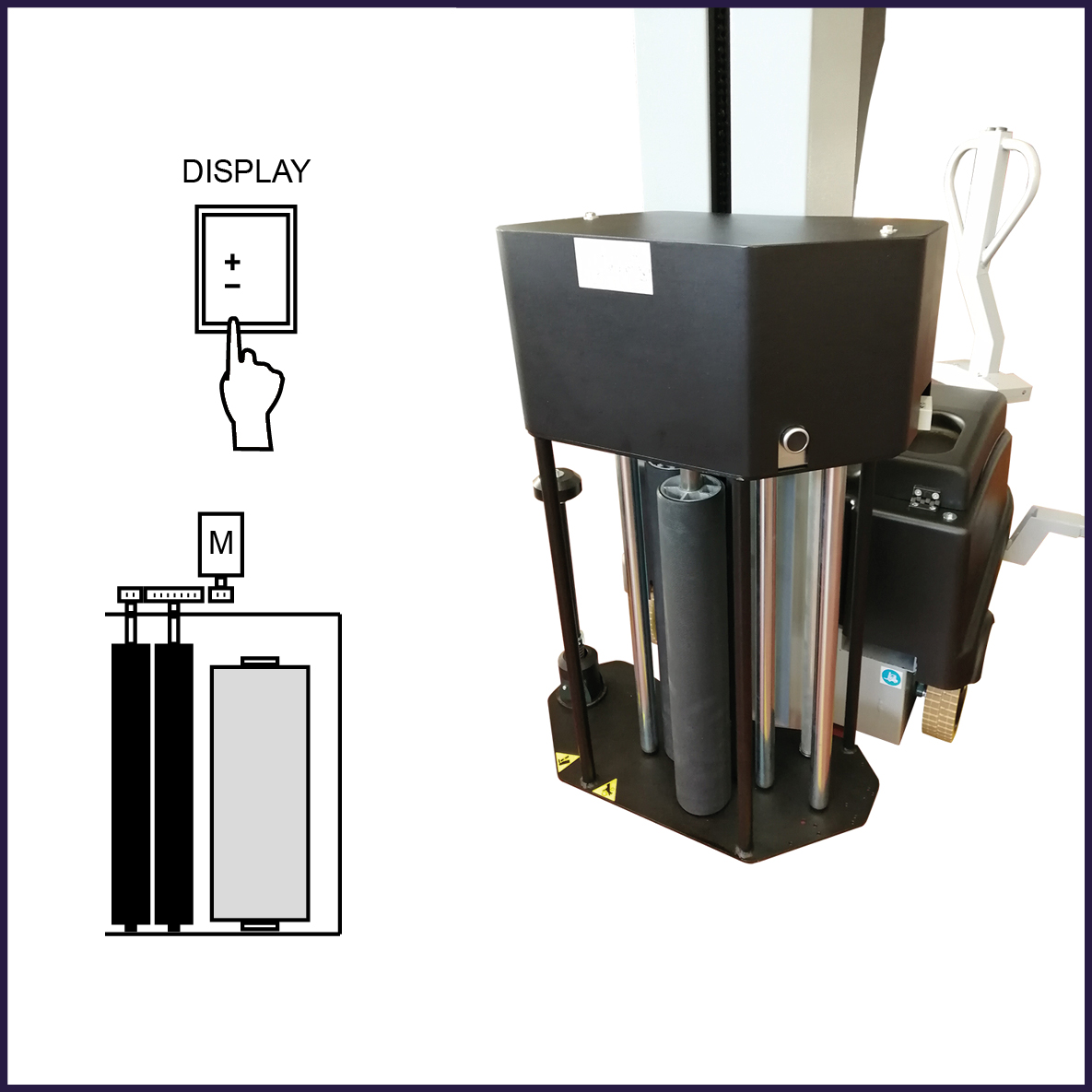

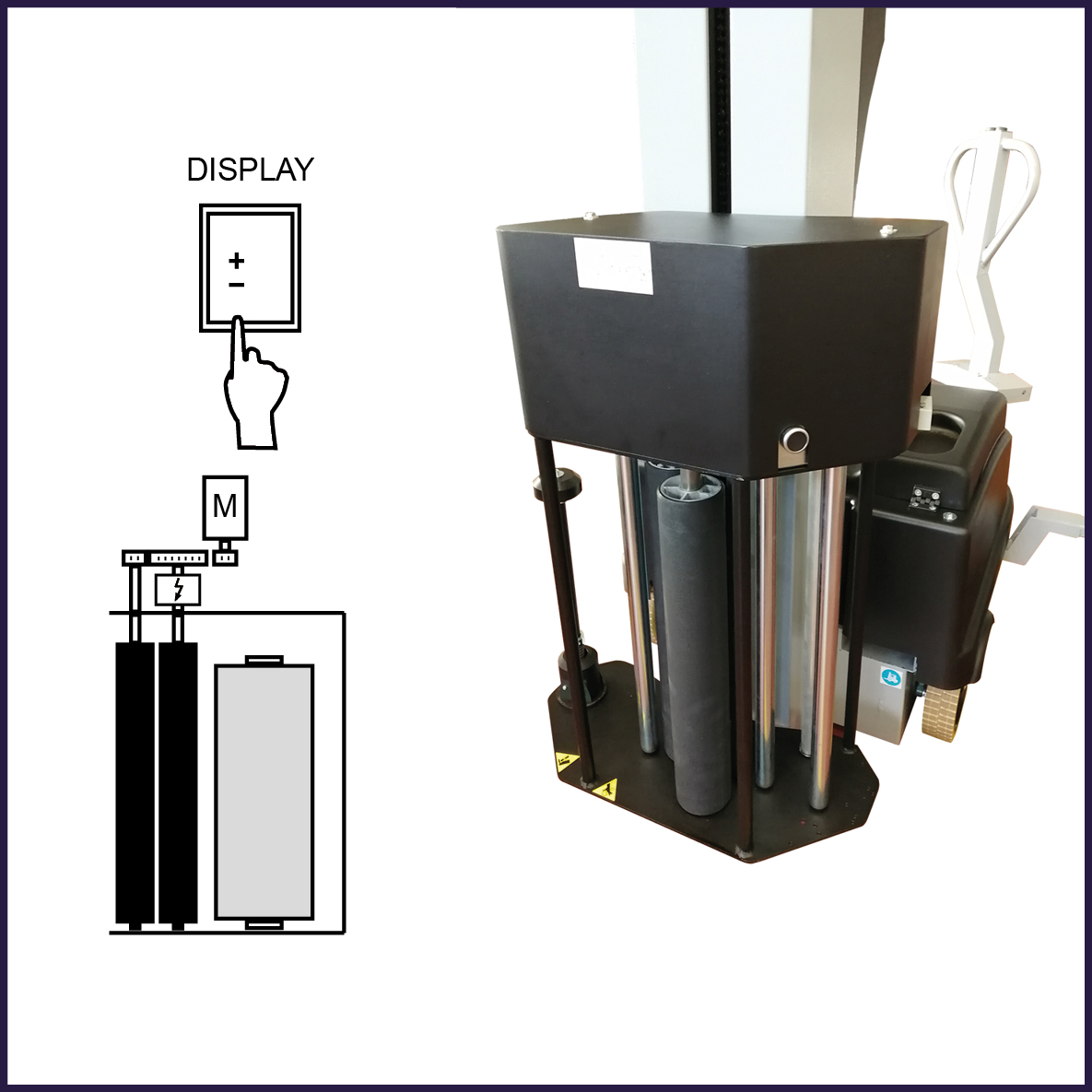

Powered by 130 Ah hermetic batteries to get a high operating autonomy. The machine structure is heavy type.

It’s good to all warehouses and is ideal for intense and heavy work.

The PLC-controlled machine is versatile and adaptable to any packaging need.

The robust and intuitive 7-inch color touch screen display provides total management of the machine's functions.

The machine also contains a menu of 100 programs to customize, store and recall when required.

The robot has been designed for medium and high wrapping quantities and designed to be equipped with pre-stretch carriages up to 300%.

Many options are available for this machine such as the film cutting, the motorized band reducer and the longitudinal cutting of the film.

Available in max wrapping height 2000 or 2400 mm.

Available in the following film coil carriage configurations: Manual Brake (FM), Electro-Mechanical Brake (FE), Power Pre-stretch (PM) and Variable Power Pre- stretch (PMV)

(other configurations on request: height 2800)

It goes where the job demands it.

The machine has been specially designed to wrap goods that cannot be moved to the packing area due to reasons of instability, a too bulky load and in any case impossible to wrap with a rotating table.

The machine is powered by batteries. It can work in any place.

The batteries used are hermetic and maintenance-free, so they can be recharged in any environment, even indoors because they do not release harmful gases.

The machine has a built-in battery charger.

The machine is easy to use.

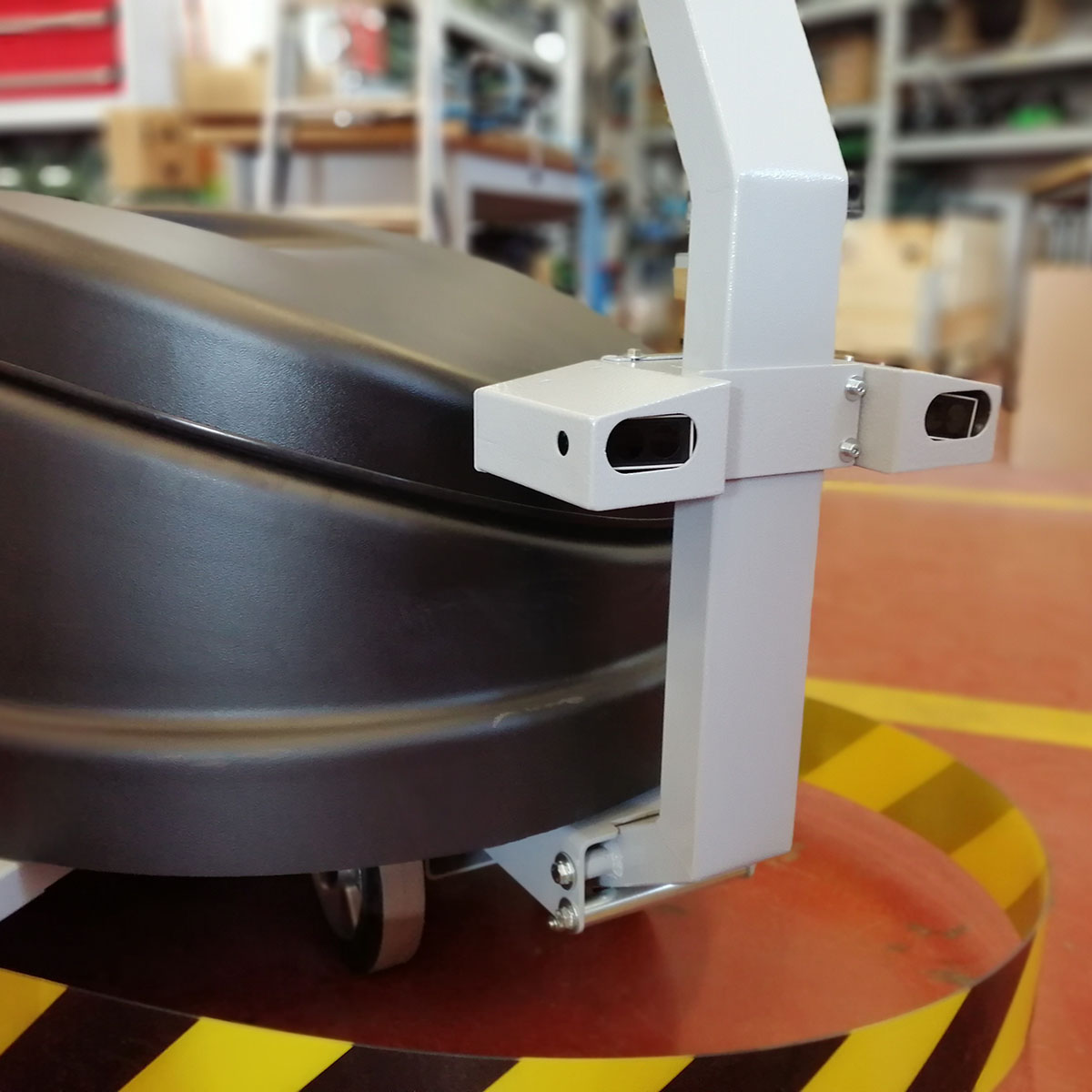

The operator just needs to bring the machine to the pallet to be wrapper so that the feeler wheel is in contact with the pallet, tie the edge of the film and press start.

The machine will automatically wrap the pallet. A photocell will automatically detect the pallet height and at the end of the cycle it will stop, ready for the next packaging.

The machine is easy to set up with the 7-inch touch screen.

The operator can select the desired wrapping program and set any adjustment, speed, number of revolutions and whatever else is available on the machine.

It will therefore also be possible to store and recall the pre-set programs. The touch screen also provides machine statistics, alerts, and diagnostics.

High quality electrical and electronic components.

The machine uses commercial PLC of the highest quality to guarantee super reliable electronics and great autonomy in the creation of customized programs.