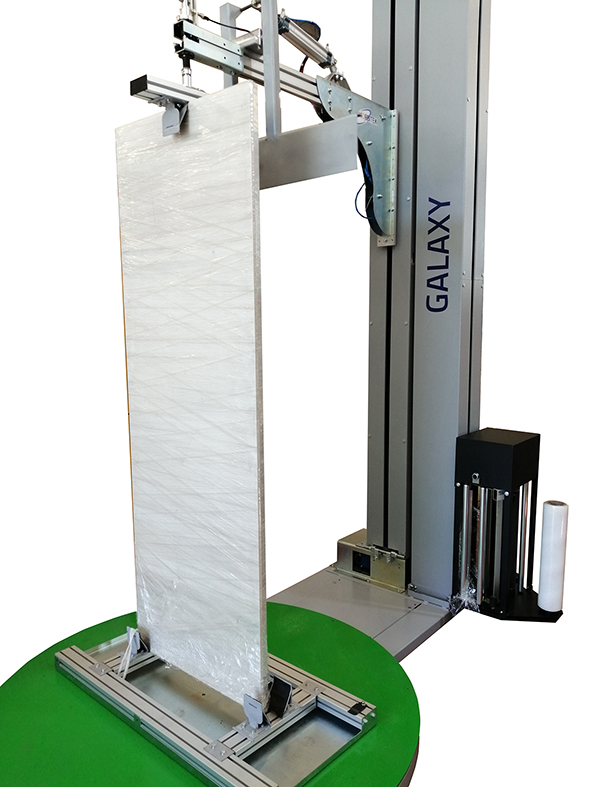

GALAXY-DOOR

Machine for wrapping doors and windows with stretch film

Machine designed for doors and windows.

The machine has a lower gripping frame fixed on the rotating plate and a motorized upper presser that slides on a sturdy steel column. The motorized presser (controlled by an inverter) is operated by the foot switch located in the loading area of the door / window.

The operator, after loading the door / window on the two lower supports, must press the pedal to control the descent of the presser until the upper support are fully inserted. At this point it will be possible to tie the film to the product and press start. The machine will start automatically to wrap the door / window. A photocell will automatically detect the height of the product and at the end of the cycle the plate will stop in phase position in order to be able to unload the wrapped product.

The lower and upper “fork” supports are adjustable in width.

Available in max wrapping height 2400, 2800 or 3200 mm.

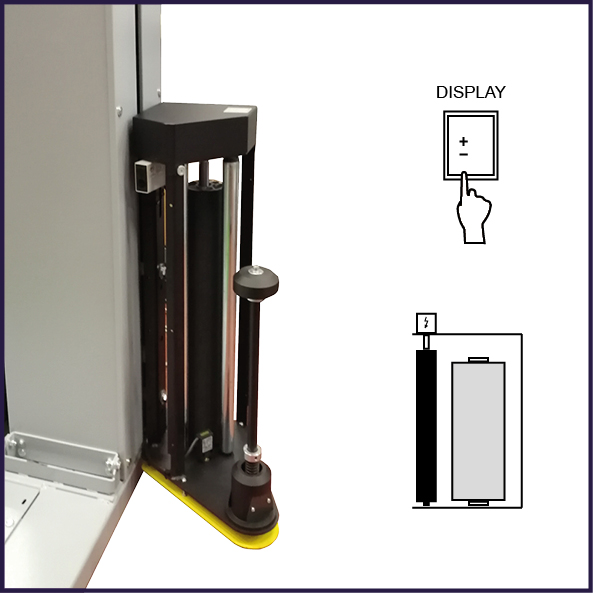

Available in the following film coil carriage configurations: Electro-Mechanical Brake (FE), Power Pre-stretch (PM) and Variable Power Pre- stretch (PMV)

(other configurations on request: plate diameter 1800, 2200 and 2400 mm)

Possibility to wrap pallets too.

The machine is easily transformed into a pallet wrapping machine. It is sufficient to remove the lower gripping frame and exclude the presser from the control panel.

Practical and robust.

The machine is built entirely of steel and is composed of a reinforced base on which derlin wheels are mounted. For this reason, the machine can also wraps products weighing up to 2100 kg (opt up to 3000 kg). The transmission is a 5/8-inch chain to ensure more precise starts and stops, with less maintenance and longer life.

Solid lifting columns.

The structure of the 2 columns is built with thick sheet metal (1.5 mm) to ensure perfect and long-lasting vertical movement of the carriage and pressing arm. The transmission of the reel-holder carriage takes place via a closed-loop chain.

Complete control of the machine.

The rotation of the Pallet, the lifting of the carriage and the pressing arm are managed by inverters which are able to vary the speeds of all movements. In this way it is possible to optimize the wrapping in each phase of the packaging.

With the inverter it is also possible to obtain a gradual start of the plate. It is also possible to obtain an exact phase stop of the plate with tolerances of only 20mm.

The machine is easy to set up with the 7-inch touch screen.

The operator can select the desired wrapping program and set any adjustment, speed, number of revolutions and whatever else is available on the machine.

It will therefore also be possible to store and recall the pre-set programs.

The touch screen also provides machine statistics, alerts, and diagnostics.

High quality electrical and electronic components.

The machine uses premium quality commercial PLC to ensure super reliable electronics.

The main components, such as inverters and contactors are from Siemens.

Optional for any windows and doors.

Pneumatic support side option mounted on the presser.

Roller conveyor option with mechanical lifting with pedal.

Bubble wrap dispenser option.

Perimeter protections with photoelectric barrier (compulsory for products weighing more than 40 kg)