GALAXY

Semi-automatic turntable machine for stretch film pallet wrapping.

High technology and reliability.

Designed to solve any packaging requirement.

High quality machine for wrapping pallets with stretch film.

The structure of the machine is heavy type, built with thick steel sheets.

It’s good to all warehouses and is ideal for intense and heavy work.

The PLC-controlled machine is versatile and adaptable to any packaging need.

The robust and intuitive 7-inch color touch screen display provides total management of the machine's functions.

The machine also contains a menu of 100 programs to customize, store and recall when required.

Available in max wrapping height 2000 or 2400 mm.

Available in the following film coil carriage configurations: Manual Brake (FM), Electro-Mechanical Brake (FE), Power Pre-stretch (PM) and Variable Power Pre- stretch (PMV)

(other configurations on request: heights 2800 and 3200 mm, plate diameter 1800, 2200 and 2400 mm)

Practical and robust.

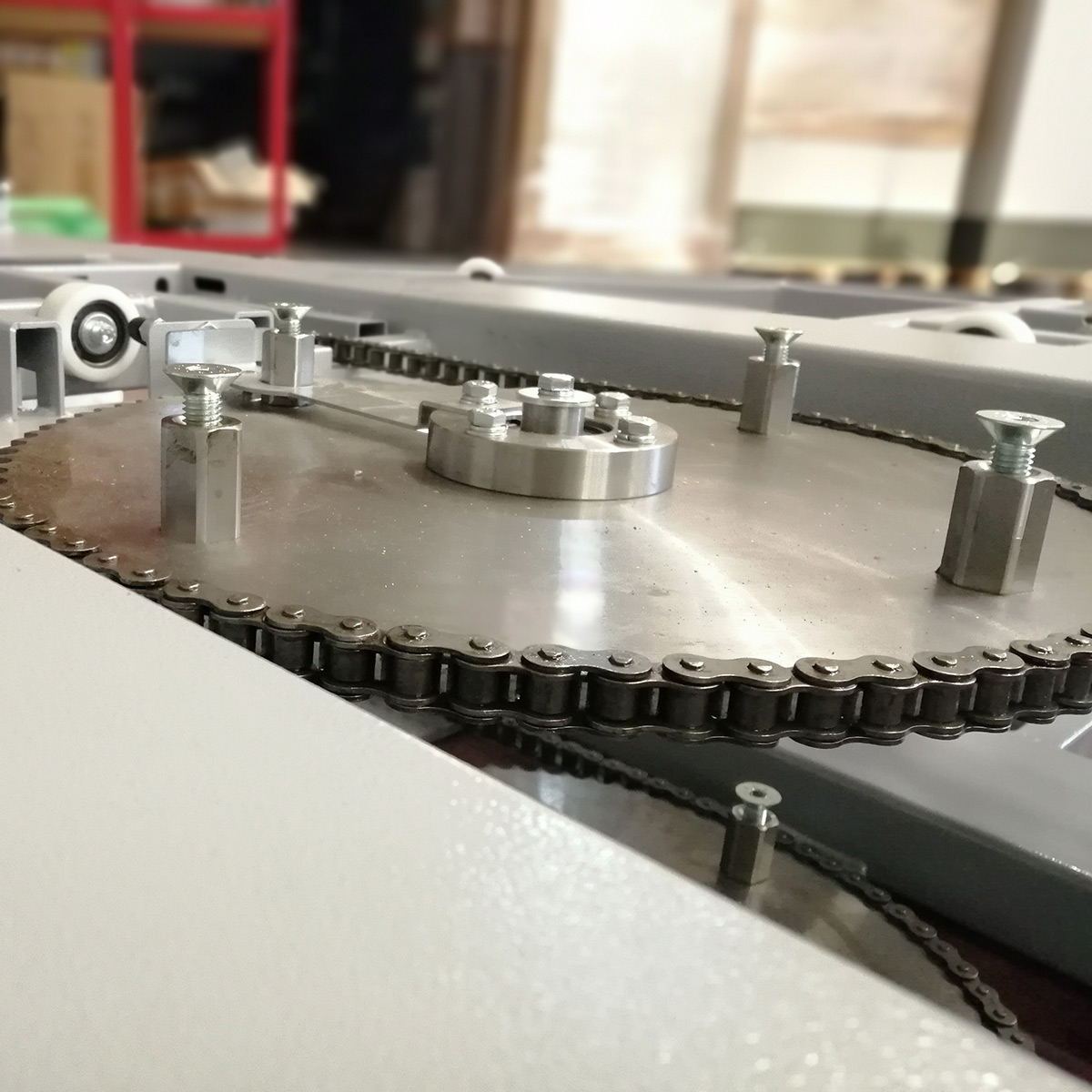

The machine is built entirely of steel and is composed of a reinforced base on which derlin wheels are mounted. For this reason, the machine can also pack pallets weighing up to 2100 kg (opt up to 3000 kg). The transmission is a 5/8-inch chain to ensure more precise starts and stops, with less maintenance and longer life.

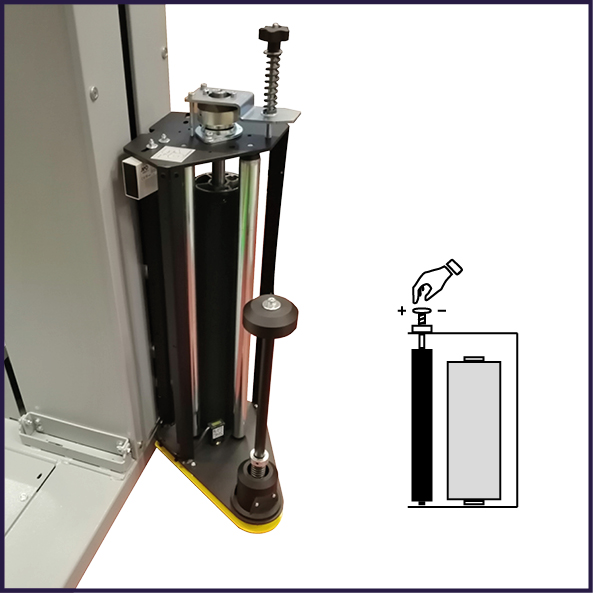

Solid lifting column.

The structure of the column is built with thick sheet metal (1.5 mm) to ensure perfect and long-lasting vertical movement of the reel-holder carriage. The transmission of the reel-holder carriage takes place via a closed-loop chain.

Complete control of the machine.

The rotation of the Pallet and the lifting of the reel-holder carriage are managed by inverters to be able to vary the speeds of all movements. In this way it is possible to optimize the wrapping in each phase of the packaging.

With the inverter it is also possible to obtain a gradual start of the plate to avoid overturning of unstable pallets. It is also possible to obtain an exact phase stop of the plate with tolerances of only 20mm.

The machine is easy to use.

The operator simply loads the pallet to be wrapped in the centre of the plate, hooks the edge of the film and press start. The machine will automatically wrap the pallet. A photocell will automatically detect the pallet height and at the end of the cycle the pallet will stop in phase position to be able to be unloaded with the forklift.

The machine is easy to set up with the 7-inch touch screen.

The operator can select the desired wrapping program and set any adjustment, speed, number of revolutions and whatever else is available on the machine.

It will therefore also be possible to store and recall the pre-set programs.

The touch screen also provides machine statistics, alerts and diagnostics.

High quality electrical and electronic components.

The machine uses premium quality commercial PLC to ensure super reliable electronics.

The main components, such as inverters and contactors are from Siemens.